The art of porcelain, pottery, and ceramics from the simplest clay cup to the most exquisite Long Phuong dinner plate—would be impossible without one crucial piece of equipment: the kiln. It’s more than just an oven; it’s the fiery heart of the ceramic studio, transforming fragile clay into durable, beautiful ceramicware. If you’ve ever wondered about the difference between a biscuit firing and a glaze firing, or simply, how hot do ceramic kilns get, you’re in the right place.

1. What are ceramic kilns?

A ceramic kiln is a special high-heat chamber designed to fire clay and transform it into durable ceramic or porcelain. It works by reaching extreme temperatures that make clay bodies hard, glassy, and resistant to water. Without a kiln, clay would remain fragile and unable to function as lasting tableware or art.

Kilns are indispensable in the world of ceramics. They facilitate the two primary firing stages:

- Bisque Firing: The first firing that converts fragile greenware (unfired clay) into hard, porous ceramic material called bisque.

- Glaze Firing: The second (and sometimes third) firing, where glazes are melted onto the bisque to create a non-porous, smooth, and often colorful finish.

To achieve these transformations, ceramic kilns must reach extreme temperatures. We’re not talking about your kitchen oven!

See more: what is ceramics and why it matters in daily life

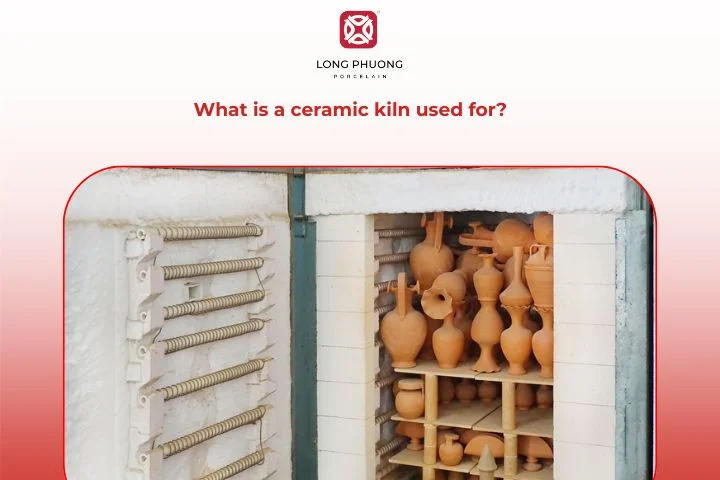

2. What is a ceramic kiln used for?

The primary use of a ceramic kiln is for firing ceramic materials. However, its application extends beyond just pots and plates. Here are the key uses:

- Firing Pottery and Dinnerware: This is the most common use, hardening clay into functional items like bowls, mugs, vases, and the high-quality porcelain sets you see from brands like Long Phuong.

- Glaze Melting: Melting glass-forming materials onto the ceramic body to create a durable, attractive, and often food-safe finish.

- Creating Ceramic Art and Sculpture: Firing large or intricate artistic pieces that require careful, controlled temperature ramps.

- Drying and Heat-Treating: Some industrial kilns are used to dry greenware before firing or for specific heat-treating processes in metallurgy.

- Glass Fusing and Slumping: While specialized glass kilns exist, some versatile ceramic models can also be used to melt or shape glass.

- Firing Bricks and Tiles: Industrial kilns fire construction materials like terracotta tiles and structural bricks.

3. 12 common types of ceramic kilns you should know about

3.1. Heat Treating Kilns

These kilns are often used in industrial or metalworking contexts, but in ceramics, they can be used for controlled pre-heating or cooling cycles. They focus on maintaining specific, uniform temperatures rather than achieving the highest heat, though some can reach ceramic temperatures.

3.2. Dual Media Kilns

These versatile kilns can operate using two different fuel sources, often electricity and gas. They offer flexibility in firing, allowing potters to choose between a clean electric fire and a potentially reduction atmosphere from gas, making them popular in educational settings.

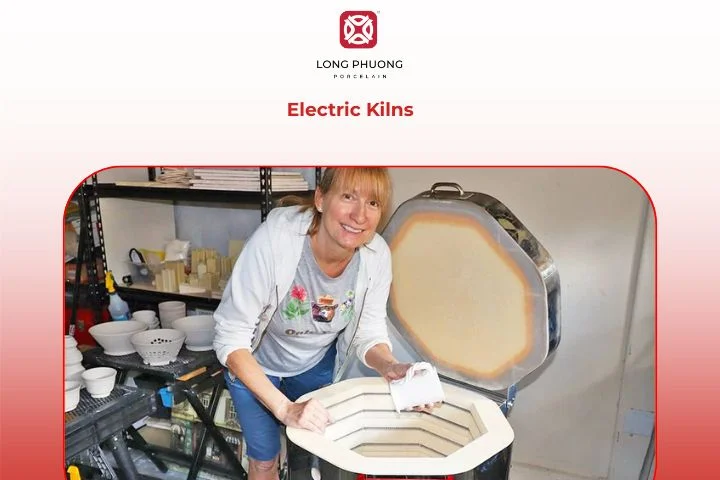

3.3. Electric Kilns

Electric kilns are the most common type for hobbyists, schools, and small studios. They are easy to use, highly controllable, and produce a clean, oxidation atmosphere (meaning there’s plenty of oxygen). This results in bright, predictable glaze colors.

Typically up to Cone 10 (about 2345∘F or 1285∘C), which is hot enough for high-fired stoneware and porcelain.

3.4. Gas Kilns

Gas kilns (fueled by natural gas or propane) are preferred by many professional artists for their ability to achieve a reduction atmosphere. Reduction occurs when oxygen is restricted, causing the flame to pull oxygen from the glazes and clay, which can produce rich, complex colors like copper reds and celadons.

Easily reach Cone 10 or even higher, up to Cone 13 (over 2400∘F or 1315∘C).

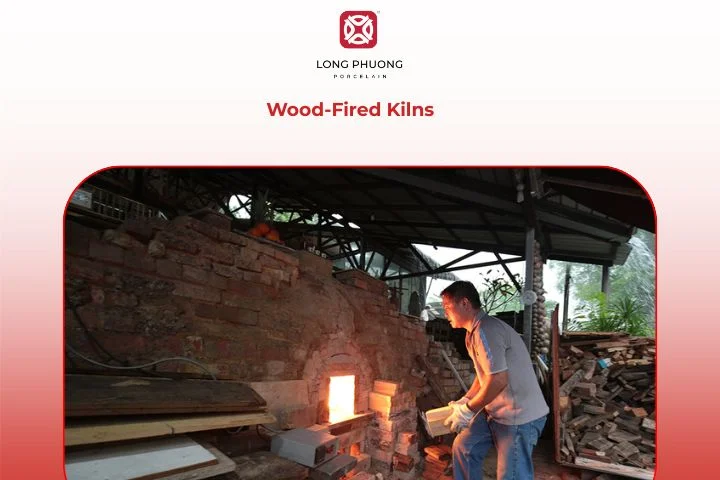

3.5. Wood-Fired Kilns

Wood kilns are arguably the most ancient and labor-intensive, but they yield some of the most unique and beautiful results. The ash from the burning wood lands on the ceramics, acting as a natural glaze. They also create a heavy reduction atmosphere.

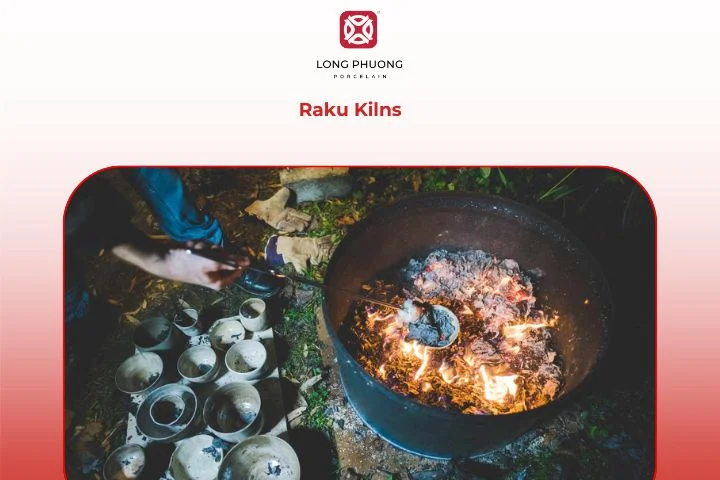

3.6. Raku Kilns

Raku is a specialized, fast-firing technique originating in Japan. Raku kilns are typically small, portable, and heavily insulated. The pieces are removed while glowing hot and placed into a container with combustible material (like sawdust), creating dramatic metallic and crackle effects. Usually fired quickly to a lower temperature, around Cone 06 to Cone 04 (1855∘F to 1945∘F or 1013∘C to 1063∘C).

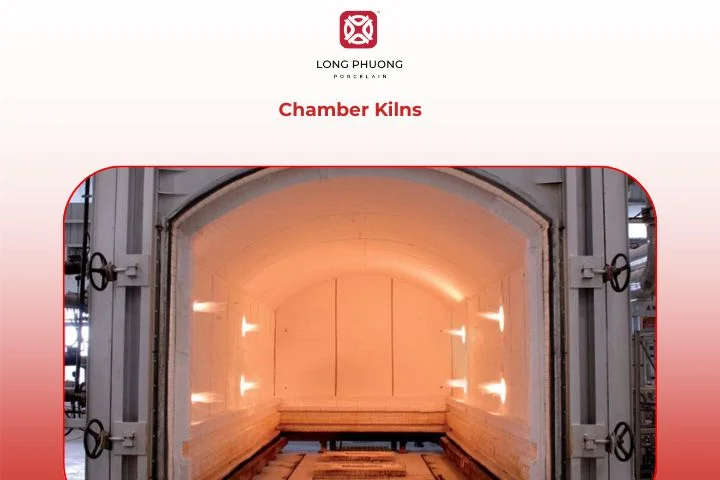

3.7. Chamber Kilns

A broad term, but often refers to larger, multi-chambered kilns where heat flows from one chamber to the next. They allow for different stages of firing to occur simultaneously, making them highly efficient for production.

3.8. Soda Kilns

A variation of a gas kiln where sodium carbonate (soda ash) and/or sodium bicarbonate (baking soda) is introduced into the kiln chamber near peak temperature. The sodium vaporizes and fluxes with the silica in the clay, creating a unique, highly textured, and glossy surface glaze.

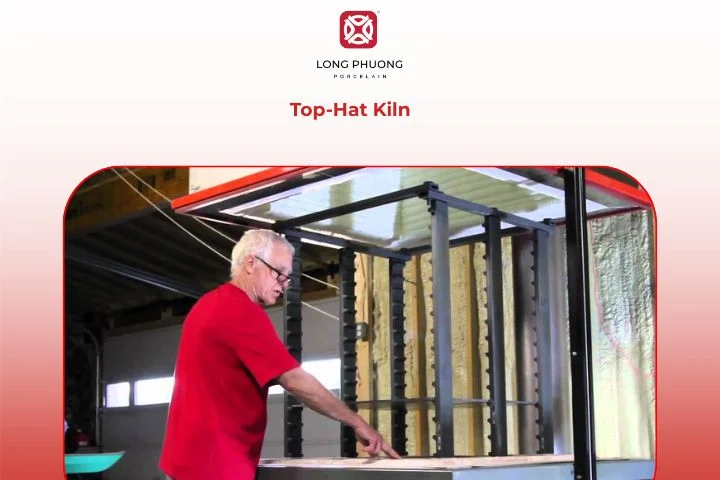

3.9. Top-Hat Kiln

A specific industrial design where the kiln’s body (the “top-hat”) is lowered onto a stationary hearth loaded with ceramic ware. This design is excellent for firing very large, heavy, or delicate items because the ware doesn’t need to be moved after stacking.

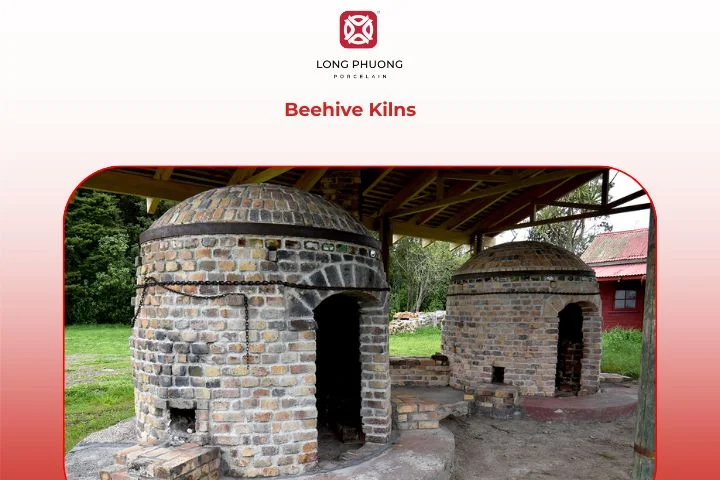

3.10. Beehive Kilns

Named for their domed, beehive-like shape, these were historically common, particularly for firing bricks and piping. The shape provides structural stability for large chambers and promotes even heat circulation from a central firebox.

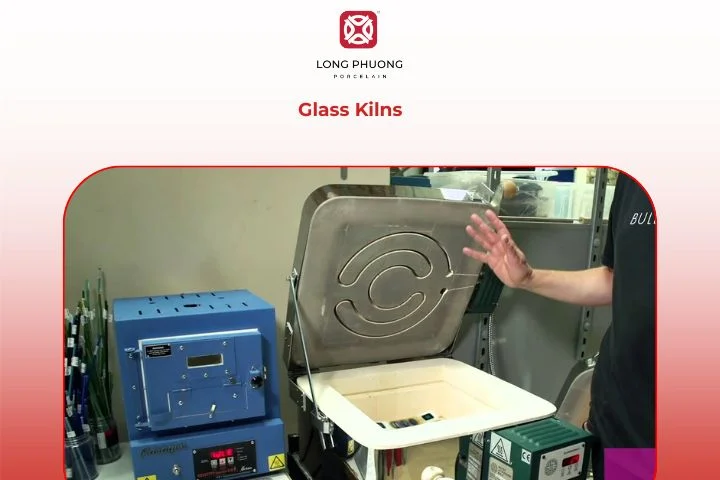

3.11. Glass Kilns

While ceramic kilns can fire some glass, dedicated glass kilns (or fusing kilns) are often wide, shallow, and have heating elements in the lid to provide radiant heat directly onto the glass. They typically don’t reach the high temperatures required for porcelain.

3.12. Industrial or Tunnel Kilns

These are massive, automated kilns used for mass production of ceramics, porcelain, bricks, and tiles. Ware is loaded onto cars that travel slowly through a long tunnel. The temperature gradient is managed so that the ware is pre-heated, fired at a continuous peak temperature, and then cooled down as it progresses. These are essential for producing consistent, high-volume products, such as those made by Long Phuong.

See more: Ceramic processing explained: steps from clay to product

4. Video tutorial on how to use a kiln for beginners

5. FAQs

5.1. What is the life expectancy of a kiln?

With proper care, a kiln can last 10–20 years. Regular maintenance like replacing elements and cleaning shelves extends its lifespan.

5.2. Is a ceramic kiln the same as a pottery kiln?

Yes. The terms are often used interchangeably. Both describe equipment for firing clay into finished ceramic.

5.3. What kiln should I buy as a beginner?

Most beginners start with a small electric kiln. It’s easy to control, requires no fuel storage, and is safe for home use.

5.4. Can you own a kiln at home?

Yes, many people own electric ceramic kilns at home. You need a dedicated space (garage, basement, or shed) with proper ventilation and the correct electrical wiring (most require a dedicated 240-volt circuit). Safety and local fire codes must always be adhered to.

5.5. Do pottery kilns use a lot of electricity?

Yes, they draw a significant amount of electricity, particularly during the peak-temperature holding phase when they are working hard to maintain how hot ceramic kilns get. The total cost depends on your local electricity rates and the size of the kiln, but a high-fire (Cone 10) cycle can easily cost $10 to $30 per firing.

5.6. Can you make pottery without a kiln?

You can air-dry clay, but it won’t be waterproof or as durable. To make lasting ceramics, a kiln is necessary.

5.7. Why are pottery kilns so expensive?

The cost reflects the materials and engineering required to handle sustained, extreme temperatures. Kilns are built with expensive, specialized components:

Insulation: High-quality refractory (heat-resistant) bricks and fiber insulation.

Elements: Specialized, durable heating elements (in electric kilns).

Controllers: Sophisticated digital controllers for precise temperature ramps.

These materials ensure the kiln can safely and consistently reach the necessary temperatures, such as those required to make the finest porcelain.

6. Where to buy a premium porcelain set?

Understanding ceramic kilns helps you appreciate the craftsmanship behind porcelain. Every beautiful dinner set, teacup, or serving dish you see has gone through careful firing in a kiln.

If you want to bring this artistry to your home, Long Phuong Porcelain offers premium-quality porcelain sets. Each piece combines modern durability with timeless elegance. Whether for daily use or special occasions, our collections showcase the finest results of skilled firing techniques.

👉 Explore Long Phuong Porcelain Collections today and elevate your dining experience with world-class craftsmanship.

Long Phuong Group Joint Stock Company

- Phone number: (+84) 989 595 866

- Email: export@longphuong.vn

- Factory: Hap Linh Industrial Cluster, Hap Linh, Bac Ninh, Vietnam

- Showroom Ha Noi: 59 Cua Bac, Ba Dinh Ward, Hanoi, Vietnam

- Showroom Ha Noi: 37 Cua Nam, Cua Nam Ward, Hanoi, Vietnam

- Showroom TP. Ho Chi Minh: 127 Le Thi Rieng, Ben Thanh Ward, Ho Chi Minh, Vietnam

Related Posts

CEO of Long Phuong Group Joint Stock Company, with more than 20 years of exploration and research to obtain the best formulas and professional experience, Long Phuong Porcelain has produced more than 400 designs of all kinds of household porcelain, Significant contributions to Vietnam's ceramic industry.

Vietnam

Vietnam